Basic Info.

Key Word 1

Sterilizer

Key Word 2

Gas Sterilizer

Key Word 3

Oxide Gas Sterilizer

Transport Package

Container

Specification

1260*800*1050

Trademark

RX

Origin

Zhengzhou

HS Code

843800

Production Capacity

10 Sets Per Month

Product Description

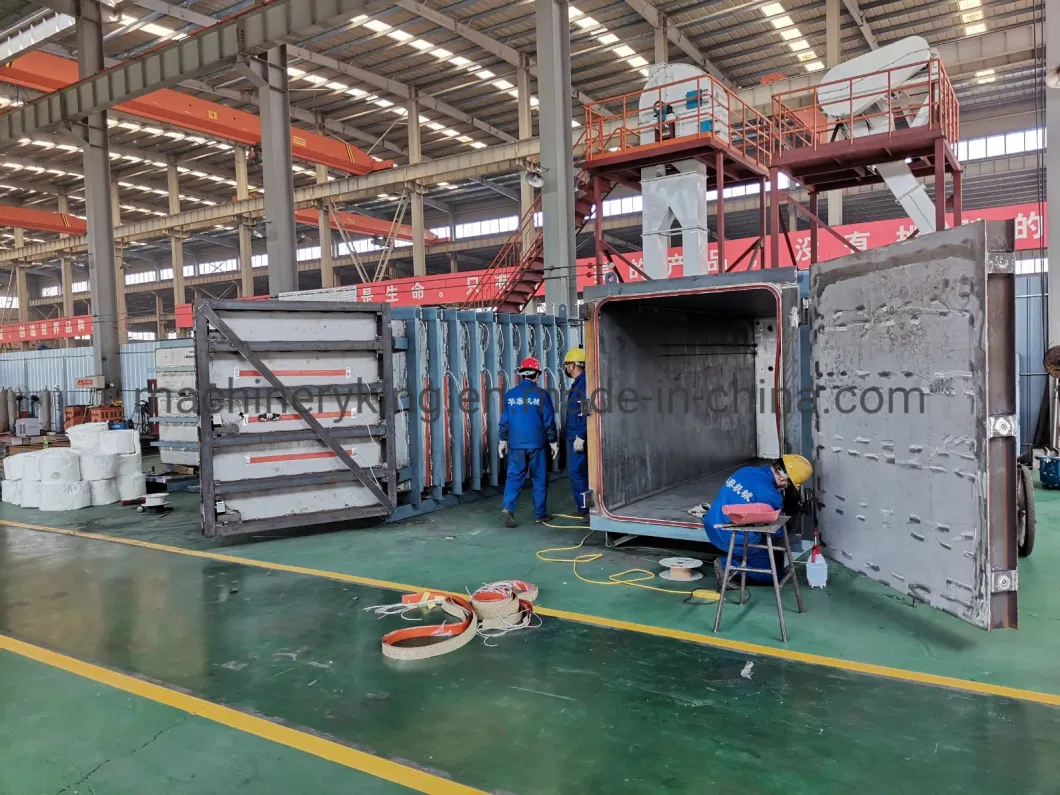

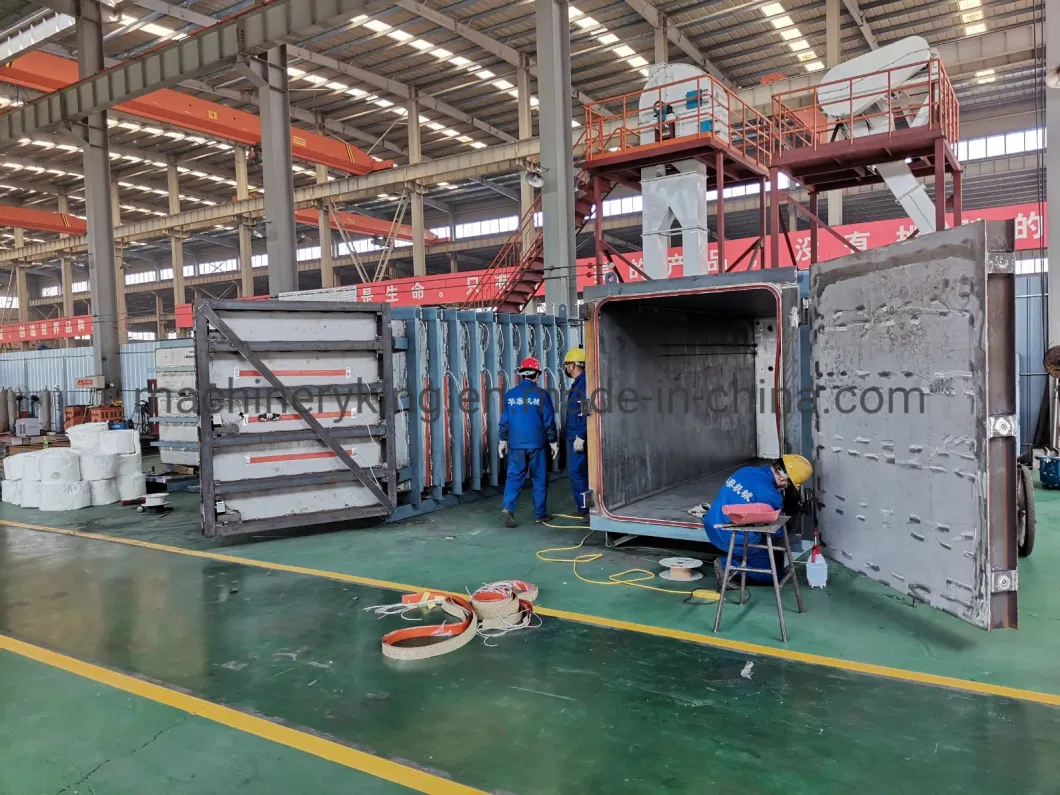

High Configuration Ethylene Oxide Gas Sterilizer Disposable Syringe

Application:

1.The dedicated programmable microcomputer control system can control temperature, pressure, humidity and

time, do timing residual gas treatment, alert, print real-time data by micro-printer.

2.The calculator control system control the machine by institute laborers. It owns two modes of operation mannual

and automatic, and friendly manmachine interface. It can control, watch over and alert the entire sterilization

process automatically including opening and closing the door; also;can do real-time record about the sterilization

parameters and the trends of temperature, pressure, humidity; can archive and print at any moment.

Medical Supplies:

Syringe, Infusion Set, Surgical Gloves, all kinds of Rubber Infusion Catheter, Oxygen devices, Suture, Anesthesia

supplies Sanitary napkins, Medical dressing.

Medical Devices:

Optical endoscopic, Pacemakers, In stent, Surgical instruments, patient's bedding, etc.

Others:

Some traditional Chinese medicine, Western medicine, Archaeological Heritage, Animal and plant specimens

Information paper, Archives and paintings,etc

HTAJ2 series large-scale ethylene oxide sterilizer is a kind of low- temperature sterilization equipment: This product is designed by using advanced computer technology, automation technology, welding technology and process on the basis of absorbing the advantages of similar products domestic and overseas.

Air replacementAutomatic ventilation, air exchange frequency and interval can be set freely

Automatic control systemOne-click start to end, the whole process is automatically completed with print record

Display status Display temperature, humidity, pressure, sterilization time, residual gas treatment time, number of times

PrinterThe whole process of sterilization information record printing, in order to verify the check.

Humidity sensorThe built-in humidity sensor automatically detects the humidity in the cavity to ensure that the humidity in the cavity is not lower than 45% RH.

Pressure sensor The inner pressure sensor automatically detects the pressure inside the cavity to ensure the accuracy and efficiency of the pressure.

Temperature sensorThe built-in temperature sensor automatically detects the cavity temperature to ensure that the cavity temperature remains within the accurate range of 50 ºC ±3 ºC.

Humidifying systemPulse humidification in the vacuum state ensures that the humidity in the cavity is uniform and controllable, and the humidity of the sterilizing chamber should be controlled within the range of 45- 80% relative humidity.

Residual gas treatment unitFiltration efficiency of filter for particle diameter ≥ 0.3 μ m,not less than 99.5%.

Sterilization chamber leakage rate The leakage rate is measured under the condition of no-load and sterilization room temperature, the test pressure is - 50kPa, and the measurement time is 1h.

[Vacuum rate] Under no-load conditions, the time for the disinfection cabinet to reach -60kPa from normal pressure should be ≤30min.

[Vacuum system] The oil-free vacuum pump is used, which is simple and convenient, the vacuum rate is fast, and the service life is long.

[Heating system] It adopts explosion-proof electric heating device, which is more convenient and quick.

[Tray rack] Use 304 stainless steel tray rack.

Sterilization chamber leakage rate] With over-voltage and over- temperature protection function, it is more safe and reliable.

[Casters] Yes.

[Alarm system] There is a high temperature alarm system and an ultra-low pressure alarm system; when the disinfection temperature of the disinfection room exceeds 59 ° C, it should be able to sound an alarm.

[Category] Class II medical instruments.

2. Medical devices:endoscope, pacemaker, artificial heart, dialyzer, attractor, oxygenator, etc.

3.Sanitary products:Women's sanitary napkin, napkin, disposable sanitary tableware, etc.

4.Medicine:some Chinese medicine western medicine, some cosmetics.

5.Textiles and biological products:cotton wool chemical fiber clothing, carpet, leather, fur products, etc.

6.RMB, ticket, medical records, archives, letters, collection of historical relics, silk satin products, animal specimens, etc.

7.Instruments:electronic instruments, optical instruments, recorder, telephone, etc.

Technical information:

Ethylene oxide gas sterilizer specification

Ø(1)Installation requirements of ethylene oxide sterilizer:

Ø1)The ethylene oxide sterilizer must be placed in a well-ventilated place, and it must not be placed near a fire source.

Ø2)In order to facilitate repair and regular maintenance, 51cm space should be reserved on each side (including the top) of the ethylene oxide sterilizer.

Ø3)Special exhaust pipes should be installed and completely isolated from other exhaust pipes of the building.

Ø(2)Ethylene oxide safety protection principles and precautions:

Ø1) Keep ethylene oxide sterilizers and cylinders or cans away from sources of ignition and static electricity.

Ø2) Ethylene oxide storage should be free of ignition sources, no rotating motor, no sun, good ventilation, and the temperature is lower than 40 ºC, but it should not be placed in the refrigerator. Dispose of in strict accordance with the relevant national storage requirements for flammable and explosive materials.

Ø3) Do not use too much force when administering or opening the bottle, so as not to spray the liquid.

Ø4)Monitor the air concentration of the ethylene oxide working environment every year.

Ø5)Ethylene oxide staff should be trained in expertise and emergency management.

Application:

1.The dedicated programmable microcomputer control system can control temperature, pressure, humidity and

time, do timing residual gas treatment, alert, print real-time data by micro-printer.

2.The calculator control system control the machine by institute laborers. It owns two modes of operation mannual

and automatic, and friendly manmachine interface. It can control, watch over and alert the entire sterilization

process automatically including opening and closing the door; also;can do real-time record about the sterilization

parameters and the trends of temperature, pressure, humidity; can archive and print at any moment.

Medical Supplies:

Syringe, Infusion Set, Surgical Gloves, all kinds of Rubber Infusion Catheter, Oxygen devices, Suture, Anesthesia

supplies Sanitary napkins, Medical dressing.

Medical Devices:

Optical endoscopic, Pacemakers, In stent, Surgical instruments, patient's bedding, etc.

Others:

Some traditional Chinese medicine, Western medicine, Archaeological Heritage, Animal and plant specimens

Information paper, Archives and paintings,etc

Description:

HTAJ2 series ethylene oxide sterilizer is a low temperature sterilization equipmentHTAJ2 series large-scale ethylene oxide sterilizer is a kind of low- temperature sterilization equipment: This product is designed by using advanced computer technology, automation technology, welding technology and process on the basis of absorbing the advantages of similar products domestic and overseas.

Air replacementAutomatic ventilation, air exchange frequency and interval can be set freely

Automatic control systemOne-click start to end, the whole process is automatically completed with print record

Display status Display temperature, humidity, pressure, sterilization time, residual gas treatment time, number of times

PrinterThe whole process of sterilization information record printing, in order to verify the check.

Humidity sensorThe built-in humidity sensor automatically detects the humidity in the cavity to ensure that the humidity in the cavity is not lower than 45% RH.

Pressure sensor The inner pressure sensor automatically detects the pressure inside the cavity to ensure the accuracy and efficiency of the pressure.

Temperature sensorThe built-in temperature sensor automatically detects the cavity temperature to ensure that the cavity temperature remains within the accurate range of 50 ºC ±3 ºC.

Humidifying systemPulse humidification in the vacuum state ensures that the humidity in the cavity is uniform and controllable, and the humidity of the sterilizing chamber should be controlled within the range of 45- 80% relative humidity.

Residual gas treatment unitFiltration efficiency of filter for particle diameter ≥ 0.3 μ m,not less than 99.5%.

Sterilization chamber leakage rate The leakage rate is measured under the condition of no-load and sterilization room temperature, the test pressure is - 50kPa, and the measurement time is 1h.

[Vacuum rate] Under no-load conditions, the time for the disinfection cabinet to reach -60kPa from normal pressure should be ≤30min.

[Vacuum system] The oil-free vacuum pump is used, which is simple and convenient, the vacuum rate is fast, and the service life is long.

[Heating system] It adopts explosion-proof electric heating device, which is more convenient and quick.

[Tray rack] Use 304 stainless steel tray rack.

Sterilization chamber leakage rate] With over-voltage and over- temperature protection function, it is more safe and reliable.

[Casters] Yes.

[Alarm system] There is a high temperature alarm system and an ultra-low pressure alarm system; when the disinfection temperature of the disinfection room exceeds 59 ° C, it should be able to sound an alarm.

[Category] Class II medical instruments.

Field of sterilizer:

1.Medical supplies: syringe, infusion device, dressing type, blood collection, intubation catheter, birth control equipment, etc.2. Medical devices:endoscope, pacemaker, artificial heart, dialyzer, attractor, oxygenator, etc.

3.Sanitary products:Women's sanitary napkin, napkin, disposable sanitary tableware, etc.

4.Medicine:some Chinese medicine western medicine, some cosmetics.

5.Textiles and biological products:cotton wool chemical fiber clothing, carpet, leather, fur products, etc.

6.RMB, ticket, medical records, archives, letters, collection of historical relics, silk satin products, animal specimens, etc.

7.Instruments:electronic instruments, optical instruments, recorder, telephone, etc.

Technical information:

| NO. | ITEM NO. | INNER VOLUME (CBM / M3) | INNER SIZE (mm) |

| 1 | PE-1 | 1 | 1260*800*1050 |

| 2 | PE-3 | 3 | 1850*1000*1650 |

| 3 | PE-6 | 6 | 2800*1350*1700 |

| 4 | PE-10 | 10 | 4500*1350*1700 |

| 5 | PE-15 | 15 | 6750*1350*1700 |

| 6 | PE-20 | 20 | 9000*1350*1700 |

| 7 | PE-25 | 25 | 10000*1500*1700 |

| 8 | PE-35 | 35 | 12000*1650*1820 |

Ethylene oxide gas sterilizer specification

| Technical Info. | Specifications |

| Machine Type | Ethylene Oxide sterilizers / Sterilization chambers |

| Chamber Capacity | 1 to 35 m3 |

| Chamber Type | Rectangular type, 1 to13 pallets (80x120cm) in single or double rows |

| Doors Type | Double doors with pneumatic sliding systems (Manual and Automatic control) |

| Chamber Material | Stainless steel construction in chamber (grade 304 or 316) |

| Hot water Circulation | Double jacket with 4 circulations systems of hot water doors and chamber. Pumps and water tank integrated |

| Steam Generator | Steam generator with tank |

| Filtration | Water treatment by filtration system |

| ETO Vaporizer | Ethylene oxide vaporizer |

| ETO Circulation | ETO circulation system (ATEX circulation pump) |

| Pneumatic Energie | Air compressor |

| Electic Energie | 380 AC, 50Hz |

| Software / Controls | |

| Software/controls | Software : Automatic and manual control, data storage, graphic recorder (temperature, humidity, pressure, time, cycle steps…). Safety password administration and operator. |

| PLC | SIEMENS or SCHNEIDER Programmable Logic Controller |

| Sensors | Pressure, temperature, humidity sensors |

| Computer | Computer with printer and desk |

| Options (systems) | |

| Sensors | EX/ATEX sensors |

| Nitrogen generator | Nitrogen generator |

| Maintenance Service | Extra Services after sales |

| Software | Software qualified FDA 21CFR part 11 |

Ø1)The ethylene oxide sterilizer must be placed in a well-ventilated place, and it must not be placed near a fire source.

Ø2)In order to facilitate repair and regular maintenance, 51cm space should be reserved on each side (including the top) of the ethylene oxide sterilizer.

Ø3)Special exhaust pipes should be installed and completely isolated from other exhaust pipes of the building.

Ø(2)Ethylene oxide safety protection principles and precautions:

Ø1) Keep ethylene oxide sterilizers and cylinders or cans away from sources of ignition and static electricity.

Ø2) Ethylene oxide storage should be free of ignition sources, no rotating motor, no sun, good ventilation, and the temperature is lower than 40 ºC, but it should not be placed in the refrigerator. Dispose of in strict accordance with the relevant national storage requirements for flammable and explosive materials.

Ø3) Do not use too much force when administering or opening the bottle, so as not to spray the liquid.

Ø4)Monitor the air concentration of the ethylene oxide working environment every year.

Ø5)Ethylene oxide staff should be trained in expertise and emergency management.