Basic Info.

Model NO.

MK-BSUHT-2

Structure

Plate

Operation

Continuous

Energy

Heat Sterilization

Property

Physical Sterilization

Type

Instantaneous High Temperature

Material Inlet Temperature

5centigrade

Sterilization Time

2-30s

Sterilization Temperature

98-138centigrade

Steam Pressure

0.4MPa

Steam Consumption

13m2

Overall Dimensions

1600*1200*1800mm

Equipment Weight

500kg

Source of Goods

Direct Deal

Texture of Material

Food Grade Stainless Steel

Transport Package

Wooden Case Packing

Specification

2t/h

Trademark

Maike

Origin

China

Product Description

Product Overview

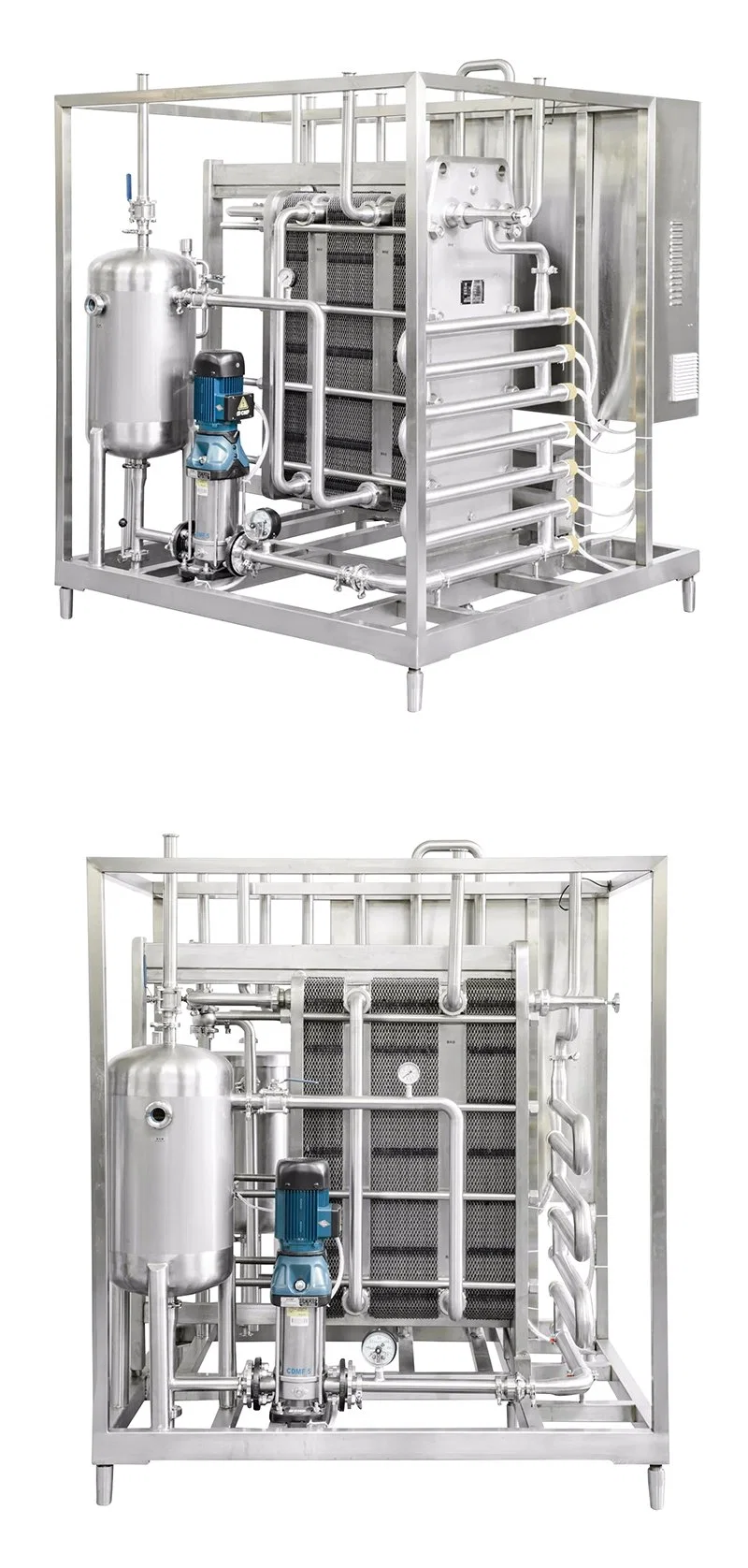

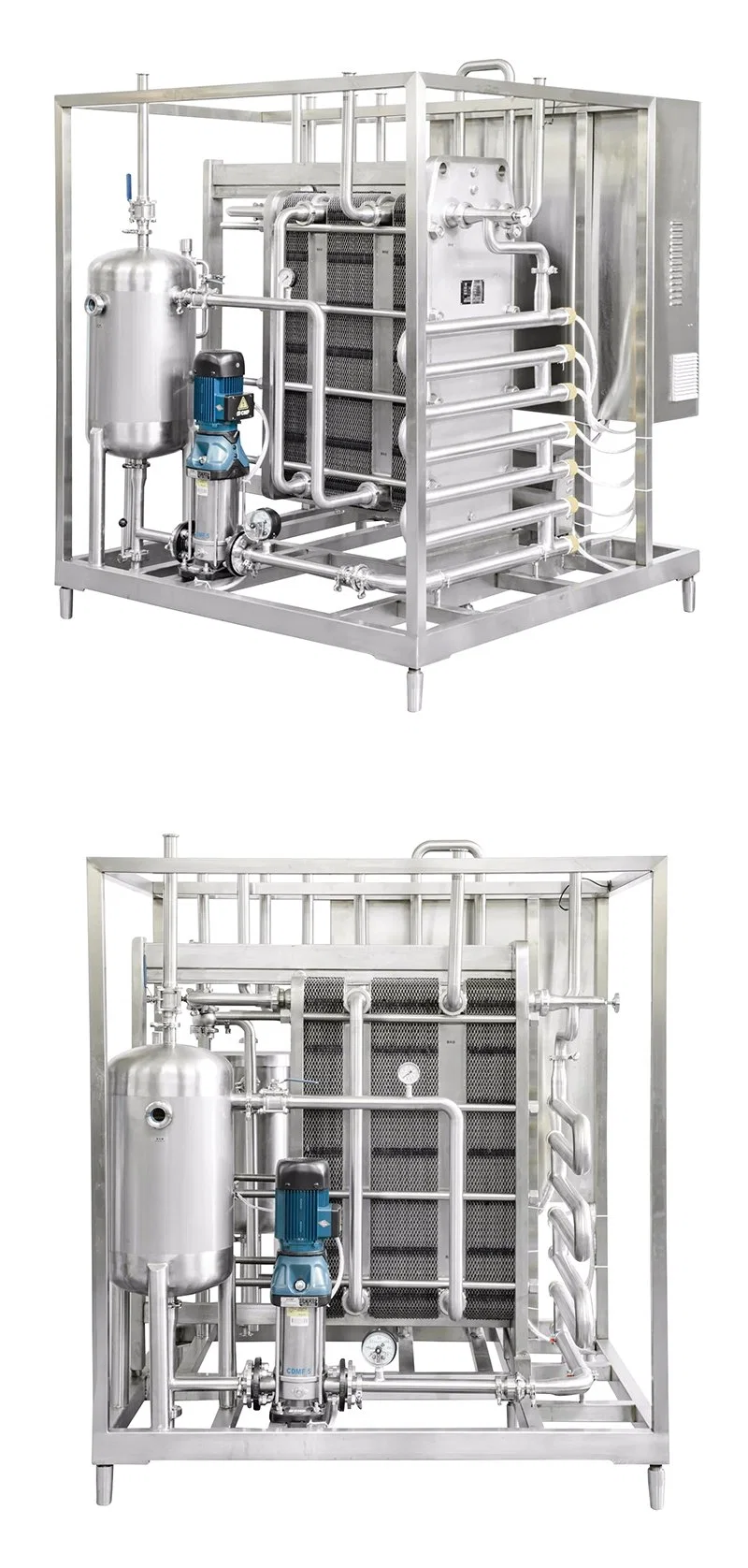

The plate sterilizer is composed of plate heat exchanger, centrifugal sanitary pump, material balance cylinder, hot water device (including hot water cylinder, hot water pump, water heater, steam manual regulating valve, etc.), electrical control box, pneumatic three-way return valve, connecting pipeline, support frame, etc., forming an integral structural form. The plate heat exchanger is composed of multi-stage process combinations such as preheating, sterilization, heat preservation and cooling according to the process requirements.

Working principle

The plate heat exchanger is the heart of the complete set of equipment. It is composed of many plates with edges, towels and sealing gaskets, as well as intermediate plates, movable compression plates, thermal insulation coils, etc. The plates are arranged in strict accordance with the design sequence of the flow chart, stacked and clamped.

Between each two plates, a liquid channel is formed.

Technical parameter

Note: The technical parameters of the plate sterilizer in the table are standard parameters, which are only for reference. We can design customized solutions according to customer needs.

The plate sterilizer is composed of plate heat exchanger, centrifugal sanitary pump, material balance cylinder, hot water device (including hot water cylinder, hot water pump, water heater, steam manual regulating valve, etc.), electrical control box, pneumatic three-way return valve, connecting pipeline, support frame, etc., forming an integral structural form. The plate heat exchanger is composed of multi-stage process combinations such as preheating, sterilization, heat preservation and cooling according to the process requirements.

Working principle

The plate heat exchanger is the heart of the complete set of equipment. It is composed of many plates with edges, towels and sealing gaskets, as well as intermediate plates, movable compression plates, thermal insulation coils, etc. The plates are arranged in strict accordance with the design sequence of the flow chart, stacked and clamped.

Between each two plates, a liquid channel is formed.

Technical parameter

| Type | MK-BSUHT-1 | MK-BSUHT-2 | MK-BSUHT-3 | MK-BSUHT-5 | MK-BSUHT-8 |

| Production capacity(T/H) | 1 | 2 | 3 | 5 | 8 |

| Material inlet temperature(ºC) | 5 | 5 | 5 | 5 | 5 |

| Sterilization time(s) | 2-30 | 2-30 | 2-30 | 2-30 | 2-30 |

| Sterilization temperature(ºC) | 95-138 | 95-138 | 95-138 | 95-138 | 95-138 |

| Steam pressure(MPa) | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| Steam consumption(m²) | 8 | 13 | 20 | 28 | 45 |

| Overall dimension(m) | 1.6×1.2×1.8 | 1.6×1..2×1.8 | 2×1.8×2 | 2.5×1.8×2 | 2.5×1.8×2 |

| Weight | 460 | 500 | 600 | 750 | 900 |