- Overview

- Product Parameters

- Application Picture

Basic Info.

Model NO.

DZG

Sterilization Information Recording and Printing

Sterilization Information Recording and Printing

Material

Stainless Steel

B.D Test

Included

LCD Controller

PLC From Siemens

GMP Confirmation Access

Fixed on The Equipment

National Patent

Door Interlock and Sealing Technology of Inner Gas

OEM

Available

Heat Preservation

Polyurethane and Pearl Rock Wool

Device

Unique Damp Proof Device

Transport Package

Export Carton Package

Specification

CE, ISO

Trademark

ROOETECH

Origin

China

HS Code

84192000

Production Capacity

500 Sets/Month

Product Description

DZG Series Dehydrated Fruit and Vegetable Food Autoclave Sterilizer for Scallion/Onion/Cabbage

Description:

Description:

Now, fruits and vegetables are very contaminated, or more or less contain more than the country's pesticides or residues, viruses and microorganisms. People are not aware of the contamination of vegetables and fruits, and there are no high concentration methods to remove them when they are eaten.

Fruit and Vegetable sterilizer does an excellent job of removing chemicals and dirt from the surface of fruit, leaving no residue, aftertaste or smell. Used for all kinds of dry vegetable and fruit , such as tomato, potato, apple, mango, guava, potato carrot, cucumber, beetroot, beef, etc. Complete stainless steel body support, all of which are specially designed by steam immersion and are dried naturally after sterilization. Steam enhances the safety and shelf life of fresh fruits and vegetables without cold storage.

Features:

1. Corrosion resistant material: 316L

The inner cavity of sterilizer is made of 316L stainless steel, which has good corrosion resistance and can resist chloride ion erosion.

2. Professional process flow

According to the characteristics of different sterilized articles, special sterilizing process parameters and processes are set up to protect sterilized articles while ensuring sterilization effect.

3. Size can be customized

According to the size of the sterilized articles, the design of sterilization chamber, high volume utilization rate, large loading capacity.

4. Isolation seal construction

Two-door structure, pressure safety interlock; Biological seal structure, can realize the biological seal before and after the sterilizer, tight sealing of the pipeline.

5. Professional loading

Special loading trolley, high loading capacity, improve work efficiency.

6. Easy to operate and safe to use

The sealed door automatically opens and closes, with safety device and manual operation device.

7. A more orderly scene

Sliding door mode, safe space

8. The operation is simple

Automatic operation, touch screen control, synchronous display of parameters

9. High stability

The main control parts are imported for higher stability and reliability

10.High safety

With alarm system and emergency stop device; All main valves have manual control mode

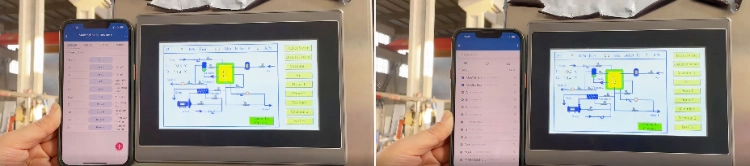

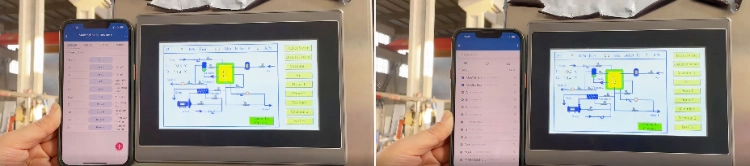

11.Remote network monitoring

With computer USB interface, can realize remote network monitoring

12.No additional service space required

The sterilizer has its own service space and no additional service space is required

13. More capacity options

Volume from one cubic to more than ten cubic options

14. Public works code requirements are low

The drainage system is cooled and the utility code requirements are low

Optional Function:

Remote Monitoring System:

The sterilizer has wireless communication function, which can be connected to the remote monitoring end through terminal routing, and the data can be directly monitored in real time via WiFi or 4G/5G network to realize remote monitoring of sterilization status, temperature, sandwich pressure, F0 value, front and back door status and other information. With high precision and high acquisition rate, the sterilization environment can be monitored 24/7, improving the operational efficiency of sterilization.

If the temperature, pressure and time data are abnormal and do not meet the pressure steam sterilization requirements, the operator can see the abnormal information on the platform.

CIP Washing Function:

Ensure the quality of the final product and meet stringent hygiene requirements. The CIP program cleans dirt while also killing microorganisms inside the equipment. With an automated and well-designed monitoring system, better cleaning results are guaranteed to ensure the production of consistently high quality products.

Description:

Description:Now, fruits and vegetables are very contaminated, or more or less contain more than the country's pesticides or residues, viruses and microorganisms. People are not aware of the contamination of vegetables and fruits, and there are no high concentration methods to remove them when they are eaten.

Fruit and Vegetable sterilizer does an excellent job of removing chemicals and dirt from the surface of fruit, leaving no residue, aftertaste or smell. Used for all kinds of dry vegetable and fruit , such as tomato, potato, apple, mango, guava, potato carrot, cucumber, beetroot, beef, etc. Complete stainless steel body support, all of which are specially designed by steam immersion and are dried naturally after sterilization. Steam enhances the safety and shelf life of fresh fruits and vegetables without cold storage.

Features:

1. Corrosion resistant material: 316L

The inner cavity of sterilizer is made of 316L stainless steel, which has good corrosion resistance and can resist chloride ion erosion.

2. Professional process flow

According to the characteristics of different sterilized articles, special sterilizing process parameters and processes are set up to protect sterilized articles while ensuring sterilization effect.

3. Size can be customized

According to the size of the sterilized articles, the design of sterilization chamber, high volume utilization rate, large loading capacity.

4. Isolation seal construction

Two-door structure, pressure safety interlock; Biological seal structure, can realize the biological seal before and after the sterilizer, tight sealing of the pipeline.

5. Professional loading

Special loading trolley, high loading capacity, improve work efficiency.

6. Easy to operate and safe to use

The sealed door automatically opens and closes, with safety device and manual operation device.

7. A more orderly scene

Sliding door mode, safe space

8. The operation is simple

Automatic operation, touch screen control, synchronous display of parameters

9. High stability

The main control parts are imported for higher stability and reliability

10.High safety

With alarm system and emergency stop device; All main valves have manual control mode

11.Remote network monitoring

With computer USB interface, can realize remote network monitoring

12.No additional service space required

The sterilizer has its own service space and no additional service space is required

13. More capacity options

Volume from one cubic to more than ten cubic options

14. Public works code requirements are low

The drainage system is cooled and the utility code requirements are low

Optional Function:

Remote Monitoring System:

The sterilizer has wireless communication function, which can be connected to the remote monitoring end through terminal routing, and the data can be directly monitored in real time via WiFi or 4G/5G network to realize remote monitoring of sterilization status, temperature, sandwich pressure, F0 value, front and back door status and other information. With high precision and high acquisition rate, the sterilization environment can be monitored 24/7, improving the operational efficiency of sterilization.

If the temperature, pressure and time data are abnormal and do not meet the pressure steam sterilization requirements, the operator can see the abnormal information on the platform.

CIP Washing Function:

Ensure the quality of the final product and meet stringent hygiene requirements. The CIP program cleans dirt while also killing microorganisms inside the equipment. With an automated and well-designed monitoring system, better cleaning results are guaranteed to ensure the production of consistently high quality products.

| Design pressure | Working Pressure | Design Temperature | Working Temperature | Heat Equilibrium | Vacuum | Steam Source Pressure | Water Source Pressure | Compressed Air Pressure |

| 0.245Mpa | 0.22Mpa | 139ºC | 134ºC | ≤±1ºC | -0.095Mpa | 0.4-0.6Mpa | 0.2-0.3Mpa | 0.6-0.8Mpa |

| Specifications | Overall Dimensions | Chamber Size | Steam Consumption | Power | Loading(kg) | Loading Cart(pcs) | Tap Water consumption | Net Weight |

| Model | L*M*H(mm) | L*W*H(mm) | (kg/cycle) | (KW) | (kg) | |||

| Single/Double Door | ||||||||

| DZG-0.36 | 1195*1220*1720 | 1000*600*600 | 50 | 1.5 | 30~50 | - | 400 | 760 |

| DZG-0.6 | 1245*1300*1880 | 1050*680*850 | 60 | 2 | 60~90 | - | 500 | 1100 |

| DZG-0.8 | 1595*1300*1880 | 1400*680*850 | 70 | 3 | 80~130 | 1 | 700 | 1300 |

| DZG-1.2 | 1695*1370*1960 | 1500*750*1100 | 80 | 3 | 120~230 | 2 | 700 | 1900 |

| DZG-2.5 | 3195*1370*1960 | 3000*750*1100 | 160 | 4.5 | 250~480 | 4 | 1200 | 2800 |

| DZG-5.0 | 3635*1800*2200 | 3400*1000*1500 | 350 | 7.5 | 500~900 | 4 | 1600 | 4500 |

| DZG-8.0 | 5635*1800*2200 | 5400*100*1500 | 450 | 7.5 | 800~1500 | 6 | 1600 | 7500 |

Details:

Company Information: