- Overview

- Product Description

- About Us

- Workshop

- Certificate

- Project case

- Our Customer

- Exhibition & Our Team

- Packaging & Shipping

Basic Info.

Dielectric Material

Glass Tube

Cooling Method

Air-Cooling

Gas

Air

Frequency

400-1000Hz

Installation

Portable

Type

Electrolytic Type

Application

Pharmaceutical, Clean Room, Lab, Hospital

After Warranty Service

Spare Parts, Video/ Online Technical Support

Power Supply

AC220V, Single Phase,50Hz(Customization Available)

Machinery Test Report

Provided

Material

Stainless Steel

Transport Package

Export Wooden Package

Specification

Standard/Customized

Trademark

Marya

Origin

China

Production Capacity

1000PCS/Month

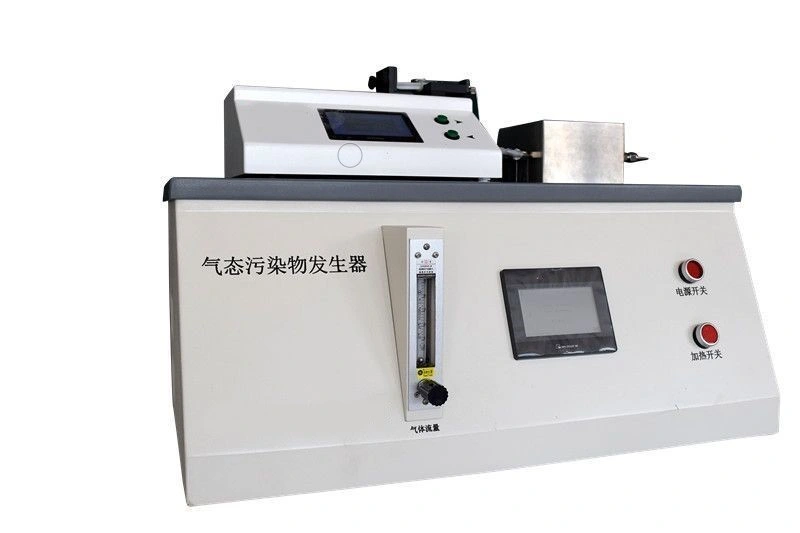

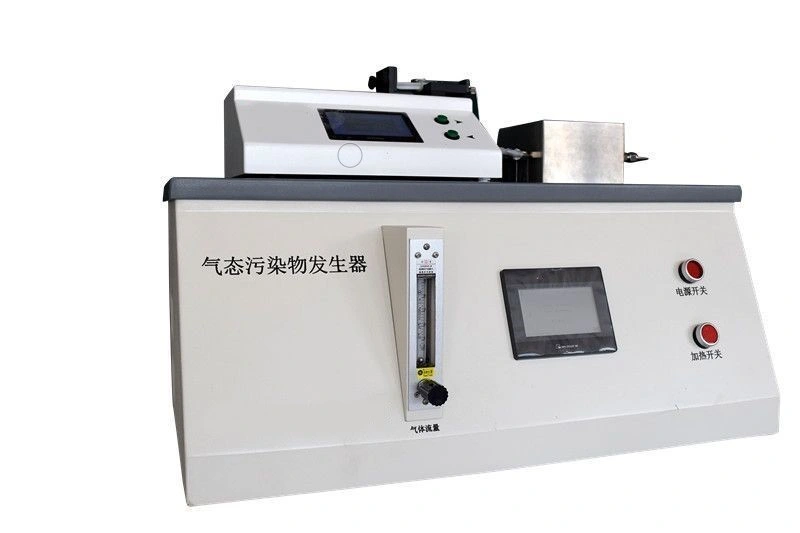

Product Description

Marya Pharmaceutical Formaldehyde Generator in pharmaceutical companies, food companies, testing and inspection companies,

The principle of formaldehyde generator sterilization: through pressure and temperature control, to stimulate alcohol and formaldehyde into chemical mixed gas, through water vapor pressure conversion to increase the penetration of the mixed gas, through temperature control to enhance the fire bacteria ability of the mixed gas, working temperature: 60°C or 78°C, fire fungicide: 3% alcohol + 2% formaldehyde solution + 95% distilled water.

The formaldehyde generator is suitable for clean production workshops, microbiological laboratories and other places with strict requirements on the number of space microorganisms. These places include: pharmaceutical companies, food companies, testing and inspection companies, etc.

2. Characteristic

1. Overview

The formaldehyde fumigation sterilizer is suitable for disinfection and sterilization products in the microbiological laboratories and pharmaceutical factories clean area. Its design is to achieve disinfection and sterilization in a simple way. When the instrument is working, it fills the space to be disinfected with formaldehyde gas. After a certain period of time, it kills the bacteria and viruses exposed on the surface of the space.The principle of formaldehyde generator sterilization: through pressure and temperature control, to stimulate alcohol and formaldehyde into chemical mixed gas, through water vapor pressure conversion to increase the penetration of the mixed gas, through temperature control to enhance the fire bacteria ability of the mixed gas, working temperature: 60°C or 78°C, fire fungicide: 3% alcohol + 2% formaldehyde solution + 95% distilled water.

The formaldehyde generator is suitable for clean production workshops, microbiological laboratories and other places with strict requirements on the number of space microorganisms. These places include: pharmaceutical companies, food companies, testing and inspection companies, etc.

2. Characteristic

- Because the purity of methanol raw material and the catalytic reaction efficiency are very high, the purity of the obtained formaldehyde is high;

- The obtained formaldehyde concentration is high, a small amount of air can meet the loading requirements of the national standard cabin;

- The rate and amount of occurrence can be precisely controlled;

- Stable concentration and high repeatability;

- Adopt air-tight glass sampler for liquid injection, anti-corrosion and no leakage;

- Suitable for long-term continuous automatic operation;

- It is not easy to block the pipeline and easy to maintain;

- Formaldehyde adjustment method: adjust the methanol loading speed and time through a precision injection pump, and then control the amount and concentration of formaldehyde;

- VOCS solution: analytical pure/chromatographic pure;

- Concentration range: 1PPM~20000PPM;

- Carrier gas: air, nitrogen; carrier gas flow: 0-50L/min;

- VOCS concentration fluctuation: ≤±2%;

- Gasification temperature: ≤200ºC;

- Low-concentration or high-concentration can be customized according to actual needs;

- The parameters can be customized according to customer requirements, and a variety of VOCS will occur;