- Overview

- Product Description

- Product Parameters

- Detailed Photos

- Product Photo Show

- Application Area

- Packaging & Shipping

- Company Profile

- FAQ

Basic Info.

Packaging & Delivery

Product Description

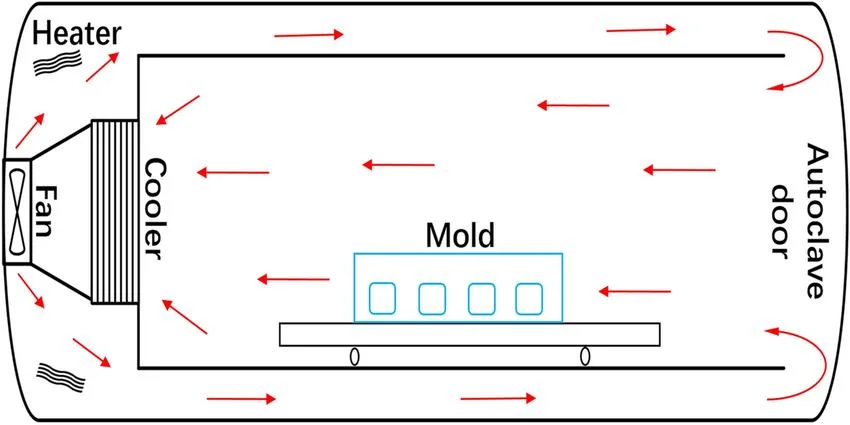

Industrial carbon fiber high Pressure Autoclave (also called industrial autoclave for composite material) is the pressure vessel specially designed and manufactured to fabricate composite material, it is one of our hot sale industrial autoclave products. Composite material (also called a composition material or composite) is made from two or more constituent materials with significantly different physical or chemical properties that produce a material with characteristics different from the individual components when combined. Industrial composite autoclave is one of the effective and most applicable techniques for composite production. In the composite manufacturing process, the assembly of a two-sided mold set that forms both surface of the panel is placed into the industrial autoclave which provides both required elevated pressure and elevated temperature.

Specifications of Composite Curing Carbon Fiber Autoclave

No. | Diameter of autoclave body(m) | Effective length(m) | Highest working pressure(Mpa) | Highest working temperature(ºC) | Design pressure(Mpa) | Design temperature(ºC) |

1 | φ1.65 | 10-30 | 1.0(1.3) | 184(195) | 1.1(1.4) | 187(198) |

2 | φ2 | 1.3 | 195 | 1.4 | 198 | |

3 | φ2 | 1.0 | 184 | 1.1 | 187 | |

4 | φ2.5 | 1.3 | 195 | 1.4 | 198 | |

5 | φ2.5 | 1.0 | 184 | 1.1 | 187 | |

6 | φ2.85 | 1.3 | 195 | 1.4 | 198 | |

7 | φ2.85 | 1.0 | 184 | 1.1 | 187 | |

8 | φ3 | 1.5 | 201 | 1.6 | 203 | |

9 | Φ3.2 | 1.6 | 204 | 1.5 | 198 | |

10 | Φ3.6 | 1.6 | 204 | 1.5 | 198 |

Our equipment can realize temperature ,pressure ,cooling and process parameters timing ,real-time on line control.

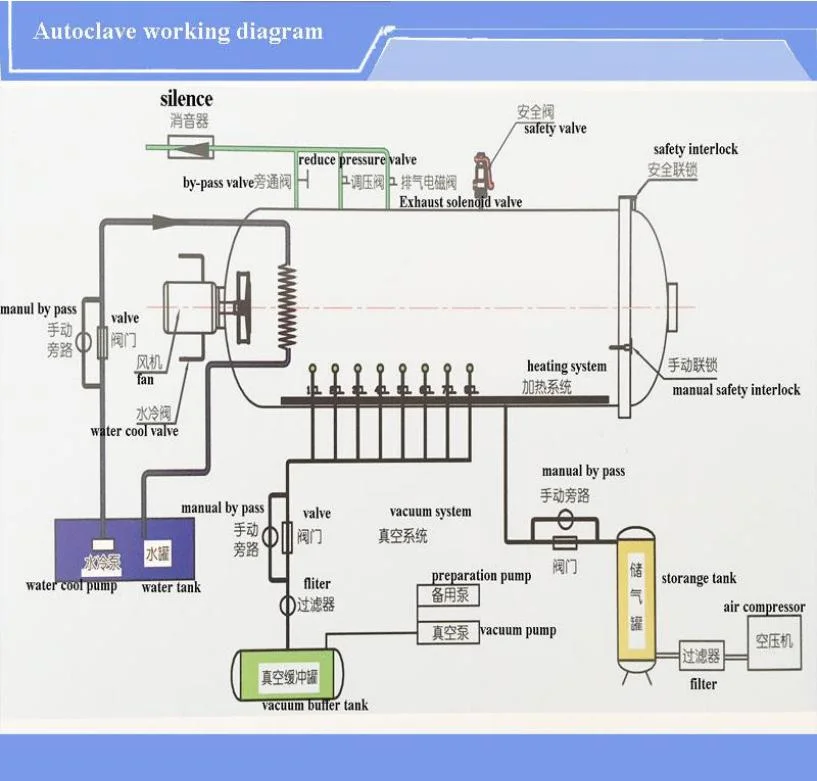

Main systems as follows:

1.Tightness of tank: It is made from tank ,tank door ,high temperature motor ,air duct heat partition layer to form into one high pressure resistant ,high temperature tank.

2.Safety interlock: It is made of pressure automatic interlock ,manual interlock, over pressure alarm device.

3.Quickly open door device: Manual or automatic quickly open design ,even If power off ,it can start and close the door

4.Sealing device: The door adopt silica gel filling air ,it can bear 500 degree, forming into one high temperature high pressure sealed container

5.Pressure system: Pressure transfer and control system include air compressor ,storage tank ,pressure control valve ,pipe ,pressure transformer ,and pressure gauge .

6.Heating system: Stainless steel heating pipe ,high temperature fan ,wind plate, insulation layer ,temperature control system .heating power satisfy with inside tank max temperature requirement and raising temperature.

7.Temperature circulation system: It made up of circulation fan ,wind plate, and guide flow cover to improve heating transfer and circulation form into uniform temperature.

8.Vacuum system: It made up of vacuum pump ,pipe ,vacuum gauge ,vacuum vale, to supply composite material vacuum condition.

9.Automatic control system: Adopt PLD and fuzzy control ,to realize the pressure, temperature ,cooling and so on full process high -precision control and in time record.

• Material of the equipment: Q345R steel which have good comprehensive mechanical property and processing property is a kind of pressure vessel special material.

• Welding method: Automatic submerged arc welding, it has advantages of high productivity, good weld quality and low labor intensity. And it also hasn't arc radiation.

• Our company has own special flaw detection to ensure the quality of products.

• The ways to open the door: Open door manually, open the door by electricity, open the door by hydraulic.

• The sealing way: With the gas-filled silica gel seal ring, the sealing effect of the equipment is significantly better than others'. And the life of the equipment is more than one year.

• Safety interlocking methods of the door of the tank: Automatic pressure safety interlocking method and Manual safety interlocking method, it solved the safety problem of wrong operation.

Our composite curing carbon fiber autoclave is widely used in many industries where need composite structural materials, such as the wing and the tail of aircraft; the solar cell substrate, sandwich panel, satellite interface bracket and rocket fairing of satellite and carrier racket; the hood and tail of the car; tennis racquet, ski of the exercise equipment; prostheses and CT board of medical equipment.

Our products have standard export package, fumigated wood box, U-steel, steel frame reach to sea transportation requirement, we have our own professional shipping company, make sure the product arrived your destination safely and as soon as possible.

Qingdao Evertech Industry Co., Ltd. is a professional pressure vessel designer, manufacturer and exporter. We have manufacturing licenses for ASME U, ASME U2,NB,PED, D1, D2 and A2 pressure vessels. Composed of more than 20 senior experts and professional engineers, the research and development team, with more than 20 years of professional experience, is committed to product design, development and program optimization, and can provide high-quality solutions according to users' requirements in different operating conditions. Company has cover an area of 70000 manufacturing base and 15000 modern manufacturing plants, can provide customers both at home and abroad with composite autoclave, high pressure autoclave, high pressure reactor, AAC autoclave, deaerator, pouring tank pressure vessel products such as more than 800 sets, pressure vessel head more than 20000 sets high quality products and services, won widespread praise.

100% Real Manufacturer

Markets:Mainly sold to Europe, America, South America, India and other countries.

Factory and certificates:

1. What is max diameter we can do for you?

The maximum diameter which our company can make is 4.5m. And the length is up to your requirements.

2. How much capacity can you treat per tank at a time?

It is up to the diameter and length of the equipment designed by your demands.

3. Is the control system manual, semi-automatic or full-automatic?

Our basic control system is full-automatic operation system.

4. Can we install the equipment by ourselves?

Of course, we will provide you with detailed installation information.

Welcome to send me email any time.

Contact : Victoria